Why replace your small engine air filter? Why is it important to clean small engines? The short answer is, because it will noticeably extend the life of your engine. Debris, dust, and grass clippings are one of the leading causes of premature small engine failure. These culprits build up slowly over time and shorten the lifespan of the engine, which ends up increasing your maintenance and overall equipment costs. The air filter is a primary line of defense in the war against engine damage.

For mower engines, grass clippings stuck to the housing and muffler area may seem like they come with the territory. Once accumulated between engine parts, grass clippings, dirt, and other grime can cause:

– Engine overheating. Clippings, dust, and dirt limit airflow, causing engines to burn too hot.

– Problems regulating engine speed. Debris can cause binding in governor linkages. In pneumatic governors, debris can block air from reaching the governor blade.

– Long-term engine damage. When exposed to dirt and debris, the pistons, cylinders, and carburetor are harmed.

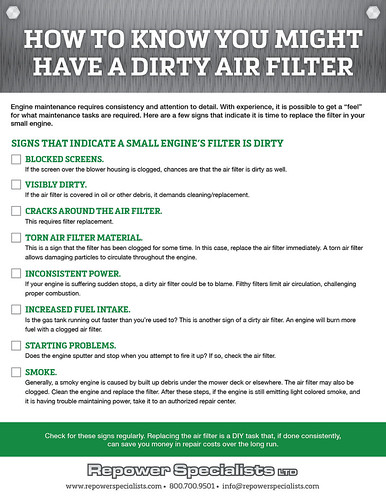

Dirty Air Filters

Air filters prevent damaging refuse from running through engines. Clean air is necessary for engine operation; combustion depends on air mixing with fuel. It is important to regularly check the air filter, as a dirty filter will strangle the engine. A clogged air filter has several damaging effects, including:

– Decreased power output. Air circulation is limited when the air filter is congested. This makes it harder for the engine to run at full power.

– Diminished fuel efficiency. When the air filter is blocked up, the engine will burn more fuel as it attempts to maintain power output.

– Difficulty starting. To start an engine, a spark, air, and fuel are required. When the air filter is clogged, air availability is limited. Sputtering and stalling is the result.

Replacing the air filter earlier rather than later will protect your engine in the long term. It is far less expensive to replace an air filter than to replace an entire engine.

Preventive Maintenance

You can limit the amount of materials clogging your air filter through preventative measures. After every use, examine the blower housing and muffler area and remove debris. Do a more thorough cleaning after every 25 hours of use, and at the end of the mowing season, prior to winter storage. To systematically inspect and clean a small engine, follow the guidelines in your manual, which will generally provide the following steps:

1. Disconnect the spark plug lead.

2. Remove the plastic blower housing.

3. Use a small bristle brush to clean the cooling fins, inside of the blower housing, and the flywheel fins.

4. Clean the flywheel cutting screen. You may need to apply a light solvent to your brush to remove stubbornly stuck debris.

5. Be sure to clean by hand, not compressed air, which can force debris deeper into the engine.

6. Check the governor linkages, and check that the linkages are able to move freely.

7. Look for debris near the break assembly, and see that the linkage and break cable move easily.

8. Once the engine is as clean as possible, replace the blower housing.

9. Reattach the spark plug.

Review the air filter at the same time, and replace if necessary.

If you work in tall and/or wet grass, plan for more frequent deep cleanings. Inspect the engine again at the beginning of each season. Rodents have been known to build nests within engines. Before firing up your small engine, check that the engine does not show signs of animal infestation.

With regular inspection and maintenance, you can keep your small engine debris-free and running smoothly for years to come.